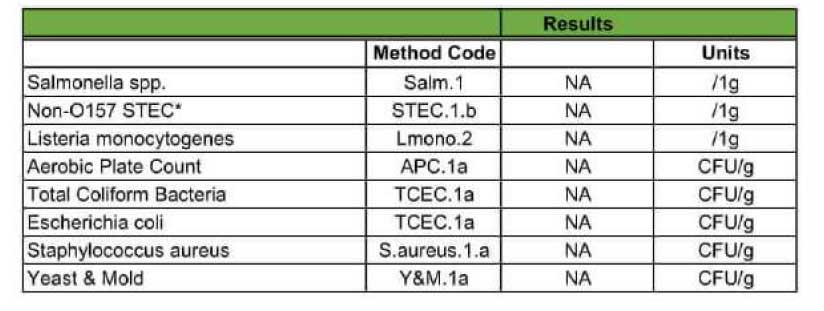

Before the CBD oil hits the shelves, there are a number of tests that must be passed, to ensure the quality of the product is safe for the user.

This is why it is so pivotal you check the lab report beforehand, as this will provide you with evidence that the batch you’re receiving has passed these tests.

What Are Microbes?

Microbes or micro-organisms are organisms that are microscopic and live in us and all around us. Some are bacteria, viruses, algae or fungi, to name a few.

Their small size makes us not consider them day-to-day, however they’re actually the most dominant life form on the planet.

Microbial research is necessary to ensure none of these microbes are present in the extract and aren’t going to affect the user’s health.

Microbial Testing Cannabis

Governments in different countries will set different standards of how much of any microbial can be present to legally be sold in the country.

For example, in the USA they have a limit of 10,000 colony forming units of mould microbials. If you have higher than this in the testing results then it has failed and your product cannot be sold.

The cannabis plant can gather various different types of mould or mildew, or pests can cause havoc to them. Just the same, the pesticides used can transfer through to the oil from the hemp extract if not grown organically.

While E. Coli isn’t commonly found in the cannabis plant, it is something they test for and has been found in the past, so it is important to check for these microbes. Whether it’s grown indoor or outdoor can have an effect, with its environment potentially playing a role.

However, microbial contamination doesn’t mean it needs to be removed as wastage, as there is a chance to potentially remedy some of it.

While most of the time the cannabis that is contaminated will occur with the cured products post-harvest before they’ve been packaged, there is also the occurrence of products failing after being packaged and passing an initial microbial test.

How Many Microbial Tests Come Back Negative?

Looking at data from the USA and speaking to a number of labs, approximately 10% of the microbial contamination tests fail.

You have to remember that, for those farmers, this will have a huge effect on their profit margins, potentially making the difference between staying afloat or not.

These farmers can then either use the failed plant material for extracts and concentrates, or they can practice some ‘remediation techniques’, which I’ll go into below.

What Is Photonic Decontamination?

Photonic decontamination is a room temperature process to prevent the growth of microbes which can affect people’s health, commonly used in a number of industries to pass FDA standards.

It has now been adopted by many cannabis growers, including some of the most renowned in the world, to ensure their end product is safe and the highest level of quality.

Also, compared to some other remediation techniques, this one doesn’t cause much damage to the plant, making it a popular method to adopt.

This process is patented by Rad Source Technologies with a 99.9% confidence level, while it won’t cause any effect on the terpenes or cannabinoids present.

The wavelength based light penetration technology reaches completely through the plant, damaging the microbes at the DNA level.

What Are Gas Decontamination Agents?

Another remediation technique is to use a gas in the process of removing biological agents that are hazardous to our health.

This method has proven popular in the past as it can cover a substantial surface area, as well as penetrating through to those hard to reach areas, but they’re really only effective at surface level contaminants.

Some bacterial spores are more resistant, so the success of this method will depend on a number of factors, such as which microorganisms are present in the cannabis and the level of soiling.

Some options are hydrogen peroxide, chlorine dioxide and formaldehyde, all with their own list of benefits and disadvantages. For example, formaldehyde is recognised as a carcinogen, while hydrogen peroxide requires quite expensive equipment.

How About Radiofrequency?

Radio Frequency technology can be implemented with the cannabis plant to kill pathogens and bugs present. This is a chemical free option commonly used in food products, most often with dates.

It offers an environmentally friendly option to the issue, helping to disinfect foods using radio frequency photons.

However, this is another method which isn’t 100% perfect, dependent on moisture, meaning dry areas of the plant will not be remediated to a sufficient level. Not just does this mean the microbes will survive, but they will most likely spread to the areas that were decontaminated.

One other negative is the potential for burns to the cannabis plant, which can affect the cannabinoid profile, the potency and the terpenes present.

Conclusion

Some crops will fail the microbial testing, even when serious levels of precautions are put in place, so beyond using them for extracts, other methods can be adopted.

Of course, there are steps that must be in place, such as ensuring the drying rooms are decontaminated during harvesting, ensuring careful and proper storage practices are in place and using either alcohol or hydrogen peroxide to clean the working area properly.

But following this, there are a number of remediation techniques that could be worth trying. Whether you’re using ozone chamber decontamination, X-ray chamber decontamination or any of the other methods, it is clear that this is a more cost effective solution to the problem and can ensure that it doesn’t go to waste.

The products shouldn’t have just below the passing threshold, you want them to be clear of any pathogens that could spread and grow, to ensure the batch is safe for selling to the public.